Benefits of Brass CNC Machining

Brass is an exceptional copper alloy that is used for several machining implementations, and it has been in use for a long time. Brass is typically shaped when zinc is added to copper. Different amounts of zinc will manufacture different kinds of brass. When the quantity of zinc is higher, it improves the strength and malleability of the sheet. What makes brass machining such popular? The need for bras machining in Toronto has always been popular, and it is purely due to the myriad of advantages it offers over other metal CNC machining technologies.

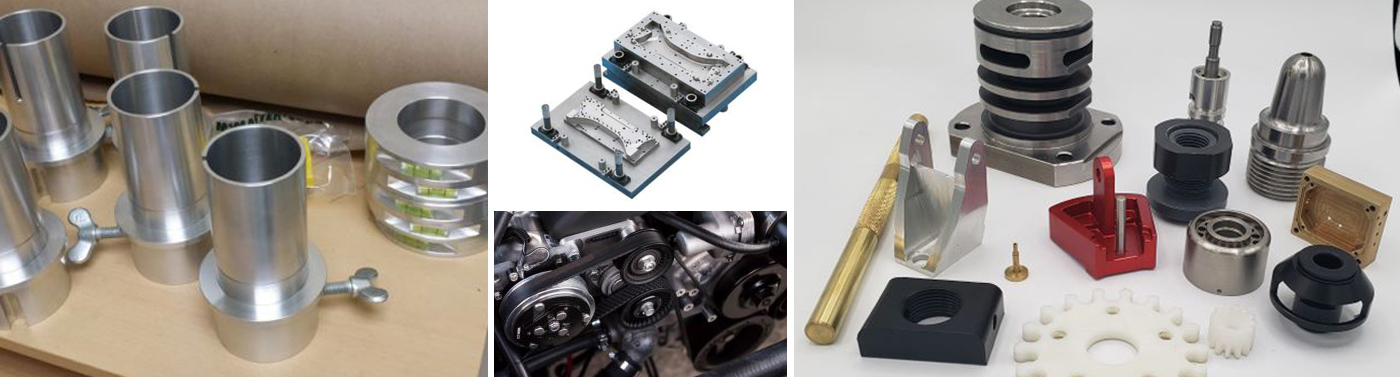

We at GTA CNC Machining Solutions have brought you the different benefits of brass machining. Take a look:

Speed Machining Services

Brass comes with glorious machineability, which is almost about 100%. The mechanical properties of brass include high strength, high durability, and shear resistance. Many studies suggest have shown machine outlets with brass have a higher speed which is usually 5 to 20 times quicker than the current which helps in increasing productivity and profitableness.

Brass Offers Precision Machining and Has Dimensional Stability

Brass is renowned for its dimensional stability. Also, brass is fitted to strict tolerance production. Due to its fewer deformation issues and high impact resistance, brass parts remain stable dimensionally.

Excellent Tool-To-Work-Piece Compatibility

The formation of chips is negligible in the process of brass machining, which is why tool wear is least. Usually, the brass rod workpieces area unit is considered the primary selection for CNC machining. These workpiece area units are highly compatible with varied CNC machining tools. The machining potency improves with tool sturdiness and resistance machining.

Increment in Productivity And Profit

Brass machining is a quick and precise machining technique, hence it helps in improving machining potency efficiently. Moreover, brass is relatively an economical and convenient material, therefore, it contributes to capital investment in-process materials. Also, the sturdiness of the tools during the process is high, which is why, the price of frequent tool replacement reduces to a great extent. Additionally, there is no requirement of a post-machining process. Altogether, these factors offer higher productivity and profits.

As brass is an alloy of copper, it can retain the chemical or physical properties of natural copper. But some of the properties of this alloy are better. That is why the materials during this method area unit are environment friendly. In addition to that brass, machining does not inject any harmful gas or chemical into the atmosphere. Also, brass is 100 percent recyclable.

We at GTA CNC Machining Solutions are known for quality and customized brass machining in Toronto. To learn more about our services, contact us today. CNC machining is one of our specialties.

For more details, stay social with us on: Facebook …